Designed to meet the need for quality and economical thermal cutting, LineaTech PRO offers a wide range of applications such as oxy-fuel flame cutting, plasma cutting and marking.

High Definition plasma cutting is controlled by the CNC with cutting parameter management for optimal cutting of fine details, small diameter holes, slots, and complicated shapes. Coupled with automatic gas consoles controlled by the CNC and a data base with automatic oxyfuel cutting parameters, the LineaTech PRO is the ideal solution for economical high- performance cutting.

MAIN FEATURES

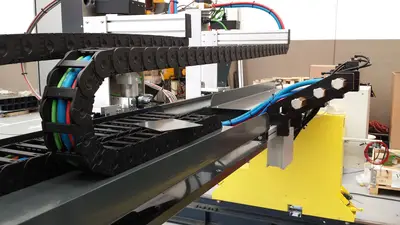

• Dual-side drives with brushless motors and digital drives

• Smooth rack and pinion motion with preloaded spring assure accurate positioning with minimum backlash

• Can be equipped with up to 4 oxyfuel stations and 1 plasma station

• Plasma cutting width up to 3.0 m on a 4.0 m wheelbase

• Oxyfuel gas distribution by 3 proportional valves controlled by the CNC

• Automatic gas management controlled by the CNC

• Library of 30 shapes with fixed cutting parameters expandable to 78 shapes

• LCD control panel with 15 in TFT color touch screen

Rail span width (min-max): 6.5 ft up to13 ft (2.0 m up to4.0 m)

Machine length: 6.5 ft (2.0 m)

Machine use length with 4 m rails: 6.5 ft (2.0 m)

Longitudinal rails beam support: HEB - STD 120 mm

Longitudinal motion: Dual side drives

Rack: Vertical teeth

Repositioning speed: 787 ipm (20 m/min)

Quality standard: ISO 9013 e EN DIN 28 206

Max no. of master carriage: 1

Max no. of slave carriage (plasma): 0

Max no. of slave carriage (oxy): 4

Gas distribution (oxy): Automatic

Max cutting thickness (oxy): 6 in. (150 mm)

Gas for oxy flame: Oxygen, propane, methane, acetylene

Max plasma power: Up to 400 amps

CNC type: SoitaabII

Parametric shape library: Standard 30 (Optional 78)

Database (oxy + plasma): Optional

We use cookies to improve your experience. Privacy Policy.