CAPACITY

Swing over the bed 22.44”

Swing over the cross slide 18.11”

Maximum turning diameter 14.17”

Maximum milling diameter 14.64”

Maximum turning length 20.47”

MAIN SPINDLE

Chuck size 8”

Spindle nose A2-6 (ASA)

Main spindle motor (Duty / Cont.) 25 / 20 hp

Spindle speed 4,500 rpm

Bore diameter 2.99”

Draw tube ID 2.67”

Spindle torque (Max) 302.9 ft.-lbs.

Spindle drive method Belt

C-axis minimum programmable angle 0.001 deg

C-axis position accuracy 0.0167 deg

C-axis repeatability ±0.0056 deg

BED, SLIDE & CARRIAGE

X axis travel 8.46”

Z axis travel 22.04”

Rapid traverse (X / Z) 945 ipm/1181 ipm

Guide ways (X / Z) Box Way

Bed structure 45deg Slant bed

Ballscrew diameter (X / Z) 1.10” / 1.57”

Axis feed thrust, Maximum (X/Z) 5,720 lbs./5,720 lbs.

Repeatability (X/Z) ±0.00008” / ±0.00012”

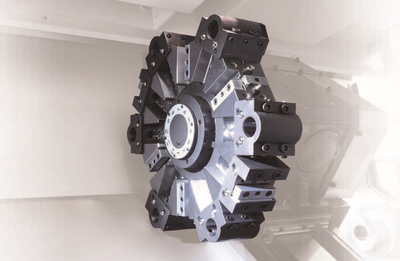

TURRET

Number of tool stations 12 (24) Tools (BMT55)

Turret indexing speed 1 station 0.2 seconds

Curvic coupling 3 Piece hyd clamp/Servo index

Coupling diameter / Clamp force 6.57” / 7,833 lbs.

Tool size (turning and facing) 1”

Tool size (boring bar maximum diameter) 1.58”

Rotating tool rpm 5,000 rpm

Rotating tool spindle motor 7.5 hp

Rotati ng tool spindle torque 25.8 ft-lbs.

Turret index repeatability ±0.000197”

TAILSTOCK

Tailstock center (Taper) MT #4 (Live Center)

Quill diameter 2.95”

Quill travel (by hydraulic) 3.14”

Maximum thrust of quill 1135 lbs.

COOLANT SYSTEM

Coolant pump motor ( 1.2 hp / 65 psi) 3hp (145 psi) [value package]*

Coolant tank capacity 53 gal.

System type Removable / Independent

HYDRAULIC / LUBRICATION

Hydraulic tank capacity 3.7 gal.

Hydraulic oil required (or equivalent) ISO VG32

Way lubrication tank capacity 0.48 gal.

Way lubrication oil required (or =) ISO VG68

MACHINE SIZE

Floor Space Requirements (LxWxH) 147” x 61” x 76”

Machine Weight 8,820 lbs.

Power Consumption 31 kVA

Voltage 220V±10%, 60 Hz, 3 phase

CNC

CNC Model Fanuc 0i-TF PLUS

Display Unit 10.4” TFT LCD Color Monitor

SHIPPING DIMENSIONS (L x W x H, Weight)

Machine and Chip Conveyor 142” x 91” x 85”, 11,464 lbs.

SMEC OPTION PACKAGE:

Tool Presetter

Auto Parts Catcher

Oil Skimmer

Programmable Tailstock (Body and Quill)

Barfeeder Interface

Manual Guide i

Chip Conveyor - Side Discharge

145 PSI Coolant Pump*

1 Set of Hard Jaws

3 Sets of Soft Jaws

3 Color Tower Light

We use cookies to improve your experience. Privacy Policy.